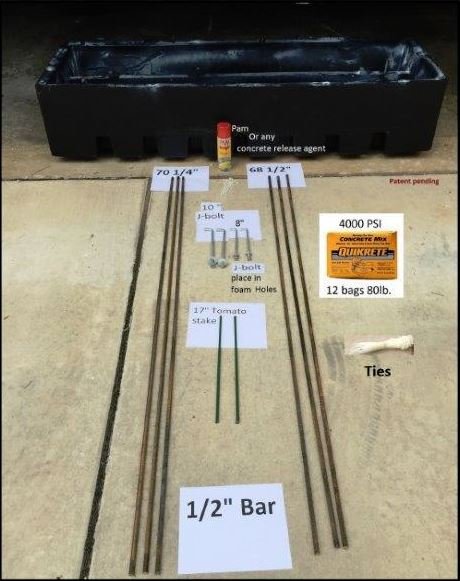

For each pour

Use tube of grease or any concrete release agent. Apply on inside.

Buy 2 20′ bars of 1/2 inch Rebar and cut: 3 pieces 70 ¼” & 3 pieces 68 ½” long.

Buy 2 tomato stakes each 17″ to place as cross members for horizontal slots (this will hold up the bars of rebar and keep them in position as concrete is poured around them).

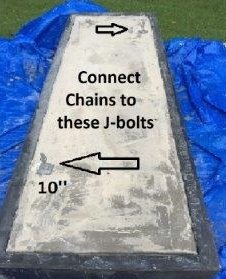

2 10″ J bolts (these will be set in concrete and used later to attach chains and your tractor will be able to lift it up while you remove the form).

2 8″ J bolts (these are used to lift the product from the top and set them in your opening).

If you have a fork lift you will not need to install these 8″ J bolts.

12 bags of 80 lb 4000 psi concrete mix.

Some tie wires or plastic zips to fasten the rebar to the J bolts and the tomato sticks.

Before setting the form, select and prepare the installation area:

3330 Vineland Rd. STE C